Loading... Please wait...

Loading... Please wait...Choosing the Correct Flap Disc

Posted by Patrick on 8th May 2014

How do I know which flap disc to use?

Flap Discs are a Coated Abrasive that have been around for the last 20 years, but have yet to catch on in the metal working industry. Flap Discs combine the grinding aspect of a grinding wheel and the polishing aspect of a sanding disc. By cutting this typical two step process down, Flap Discs save the users time and money. There are many different aspects to consider when deciding which flap disc is right for your application. At Panther Industrial we have a large assortment of Coated Abrasives, check us out on the web www.pantherindustrial.com or give us a call at (888) 857-0165.

Abrasive Material:

Aluminum Oxide - General Purpose, can be used on Ferrous and Non-Ferrous Metals. Great for rust removal, light deburring and all-purpose sanding/grinding. It is more economical for smaller jobs. Recognized by its red color. Click here to take a look at Garryson Brand Aluminum Oxide Flap Discs!

Zirconia Alumina- Premium grain for heavy duty applications and longer working life. For use on ferrous and non-ferrous metals. This abrasive material is great at grinding, blending, deflashing and stock removal. Great for people who want to get the most life out of their flap disc. Recognized by its blue color.

Click here to take a look at our Garryson Brand Zirconia Flap Discs!

Design Type (Shape):

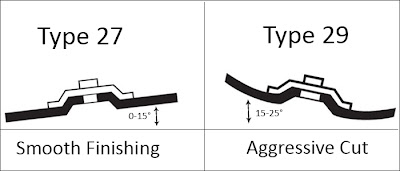

Type 27 - This type has a more flat shape, it is great for use on flat grinding surfaces. Most efficient when used between a 0-15° angle. Great choice for smooth finishing.

Click Hereto take a look at our Mercer T27 Flap Discs.

Type 29 - This type flap disc has a more conical shape, they are angled at 10°, which is ideal for contour and edge work. They are most efficient when used between a 15-25° angle. The angled flaps on this type provide greater surface contact resulting in a great choice for an aggressive cut.

Click Here to take a look at our Mercer T29 Flap Discs.

Density Type:

Standard Density: General purpose discs intended for heavy duty applications and rapid stock removal.

High Density: Between 40-60% more material than standard discs, these high density discs are provide a longer life and softer grind. The thicker design conforms to irregular shapes, which is ideal for working on curved surfaces.

Grain Size:

Also known as grit. This refers to the size of particles used in the abrasive material. The grit sizes on flap discs range from 24to120.

24 being very coarse and used for extremely fast removal of material.

120 being very fine and used for finishing/polishing.

Why use flap discs over Grinding Wheels?

Flap discs have faster stock removal and provide a smoother finish. They provide cooler cutting that is less prone to glazing. They are light weight and easy to control, with less vibration that results in less operator fatigue.

Why use flap discs over Resin Fibre Discs?

Flap discs have can last up to 20 times longer than sanding discs, fewer disc changes means reduced labor costs. They provide a more consistent finish. They also do not require a backing pad.

No matter what your use,Panther Industrial has the right flap disc for you. Please check out our website at www.pantherindustrial.com or give us a call at (888) 857-0165 and we would be happy to help you decide which product will benefit you the most!